The integration of 3D printing in healthcare has revolutionized how prosthetics are designed, manufactured, and distributed. Traditional prosthetics often come with high costs, long production times, and limited customization. However, the advent of 3D printable prosthetics has brought affordability, efficiency, and personalization to this life-changing field.

Here, we’ll explore how 3D printing and prosthetics are related, the advancements made in 3D printing in healthcare, and the profound impact it has on patients and medical professionals alike.

The Role of 3D Printing in Prosthetics

1. Customization and Personalization

One of the biggest challenges with traditional prosthetics is achieving a perfect fit. No two patients are alike, and a poorly fitted prosthetic can lead to discomfort and limited mobility. With 3D printable prosthetics, each design is tailored to the individual’s exact measurements, ensuring a snug and comfortable fit.

2. Cost Efficiency

Traditional prosthetics can cost thousands of dollars, making them inaccessible for many individuals, especially in underprivileged regions. 3D printable prosthetics drastically reduce production costs, allowing for affordable options without compromising quality.

3. Rapid Production

Conventional prosthetic manufacturing involves lengthy processes, delaying the delivery to patients. 3D printing in healthcare has shortened these timelines significantly, enabling faster production and delivery of prosthetic devices.

4. Complex Designs Made Simple

3D printing allows for the creation of intricate and lightweight designs that were once impossible or cost-prohibitive using traditional methods. This is especially beneficial for children, as their prosthetics need frequent replacements due to growth.

How 3D Printable Prosthetics Work

1. Scanning and Modeling

The process begins with a digital scan of the patient’s limb. This data is then used to create a CAD model, which forms the foundation for the prosthetic’s design.

2. 3D Printing the Prosthetic

Using advanced 3D printer designs, the prosthetic is fabricated layer by layer. Materials like PLA, ABS, or even specialized biocompatible materials are used depending on the requirements.

3. Finishing and Assembly

Once printed, the prosthetic is refined, assembled, and fitted. Adjustments can be made quickly and cost-effectively if needed.

Real-World Applications of 3D Printing in Prosthetics

1. Pediatric Prosthetics

Children often outgrow their prosthetics, making frequent replacements necessary. 3D printable prosthetics offer a cost-effective solution, enabling families to keep up with these changes without financial strain.

2. Prosthetics for War and Disaster Victims

In regions affected by war or natural disasters, 3D printing in healthcare provides a rapid response, enabling the creation of affordable prosthetics for those in need.

3. Sports and Performance Prosthetics

Athletes can benefit from custom 3D printable prosthetics designed for their specific sports, enhancing performance and comfort.

4. Functional Aesthetics

Beyond functionality, 3D printing allows for aesthetically pleasing designs that reflect the wearer’s personality. Patients can choose colors, patterns, or even themed designs.

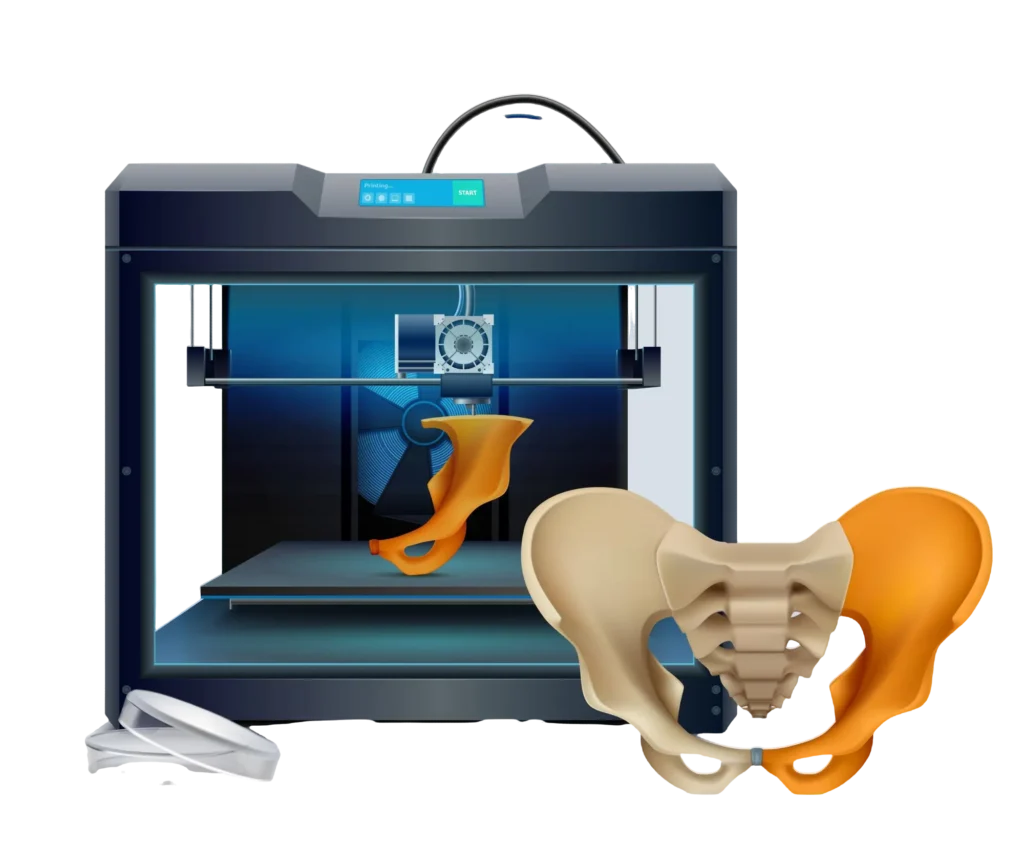

Benefits of 3D Printing in Healthcare Beyond Prosthetics

While 3D printable prosthetics are a remarkable application, the technology is making waves in other areas of healthcare as well:

- Surgical Planning: Doctors use 3D-printed models of organs for pre-surgical planning.

- Custom Implants: Personalized implants for orthopedics and dentistry are becoming commonplace.

- Medical Equipment: Cost-effective and custom-designed surgical tools can be created quickly.

Challenges of 3D Printable Prosthetics

- Material Limitations: Biocompatibility and durability of materials still require ongoing research.

- Regulatory Hurdles: Prosthetics must adhere to stringent medical standards and approvals.

- Skill Requirement: Designing 3D printable prosthetics requires expertise in CAD modeling and 3D printing.

Future of 3D Printable Prosthetics

The future of 3D printing in healthcare is bright, with continuous advancements in materials, printer capabilities, and design software. As accessibility improves, 3D printable prosthetics will likely become a standard in the medical field, transforming lives globally.

Why Choose Us to Learn 3D Printing?

If you’re inspired by the transformative power of 3D printing in healthcare and want to master this cutting-edge technology, our institution is here to guide you. Recognized as one of the best institutes for 3D printing courses in India, we offer:

- 6-Month CAD Modeling and 3D Printing Course: Gain comprehensive knowledge in designing and printing prosthetics and other healthcare-related applications.

- 3-Month Short-Term 3D Printing Course: A fast-paced program designed for beginners or professionals seeking to upskill quickly.

Join us to learn the skills needed to design and create life-changing 3D printable prosthetics and make a meaningful impact in the field of healthcare. Start your journey with us today!