3D printing has revolutionized industries, enabling rapid prototyping, personalized manufacturing, and groundbreaking innovations. However, as promising as this technology is, it’s not without its challenges. From technical hiccups to design errors, many users face barriers that can hinder the success of their projects.

This comprehensive guide addresses the most common challenges encountered in 3D printing and designing, provides actionable solutions, and highlights how expertise in 3D printer technologies can make a significant difference.

Understanding the Basics of 3D Printing

Before delving into the challenges, it’s important to grasp the basics of 3D printer technologies. At its core, 3D printing involves creating three-dimensional objects by layering material, guided by a digital design. This process, also known as additive manufacturing, depends on several key components:

- 3D Printer Design: The architecture and setup of the printer, including build size, nozzle type, and frame stability.

- Slicer Software: Converts 3D models into instructions the printer can execute.

- Material Choice: Filaments like PLA, ABS, PETG, and advanced options such as carbon fiber or metal.

With this foundation, let’s explore the common hurdles users encounter.

1. Poor Bed Adhesion

The Challenge:

One of the first obstacles users face is the inability of the first layer to stick to the print bed. This often leads to warped prints or total print failures.

Solution:

- Use adhesive aids such as glue sticks, hairspray, or painter’s tape on the print bed.

- Level the bed manually or use an automatic bed leveling system for consistent results.

- Ensure the print bed is heated to a temperature suitable for your material.

Proper 3D printer design and consistent maintenance can significantly reduce adhesion issues.

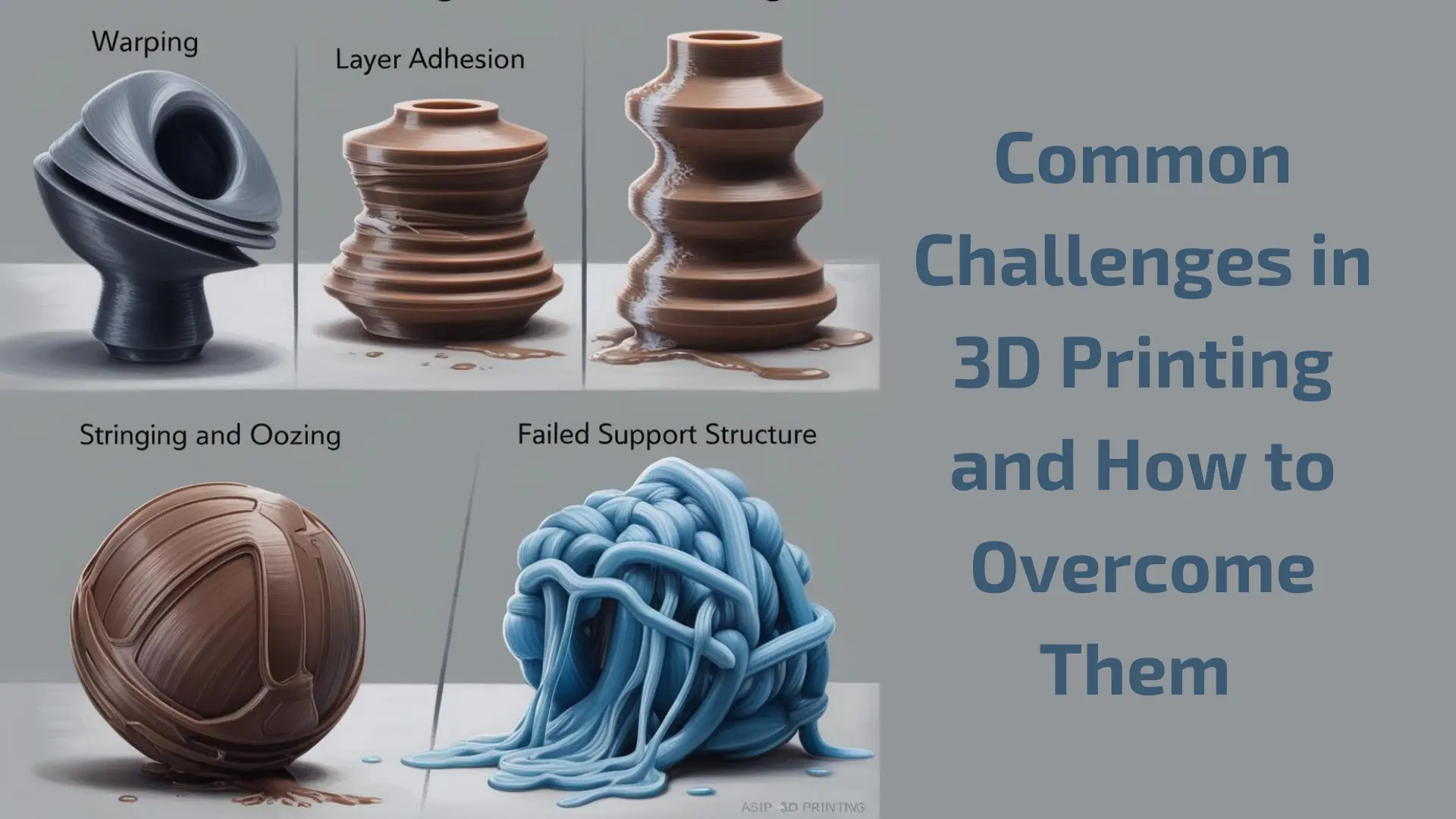

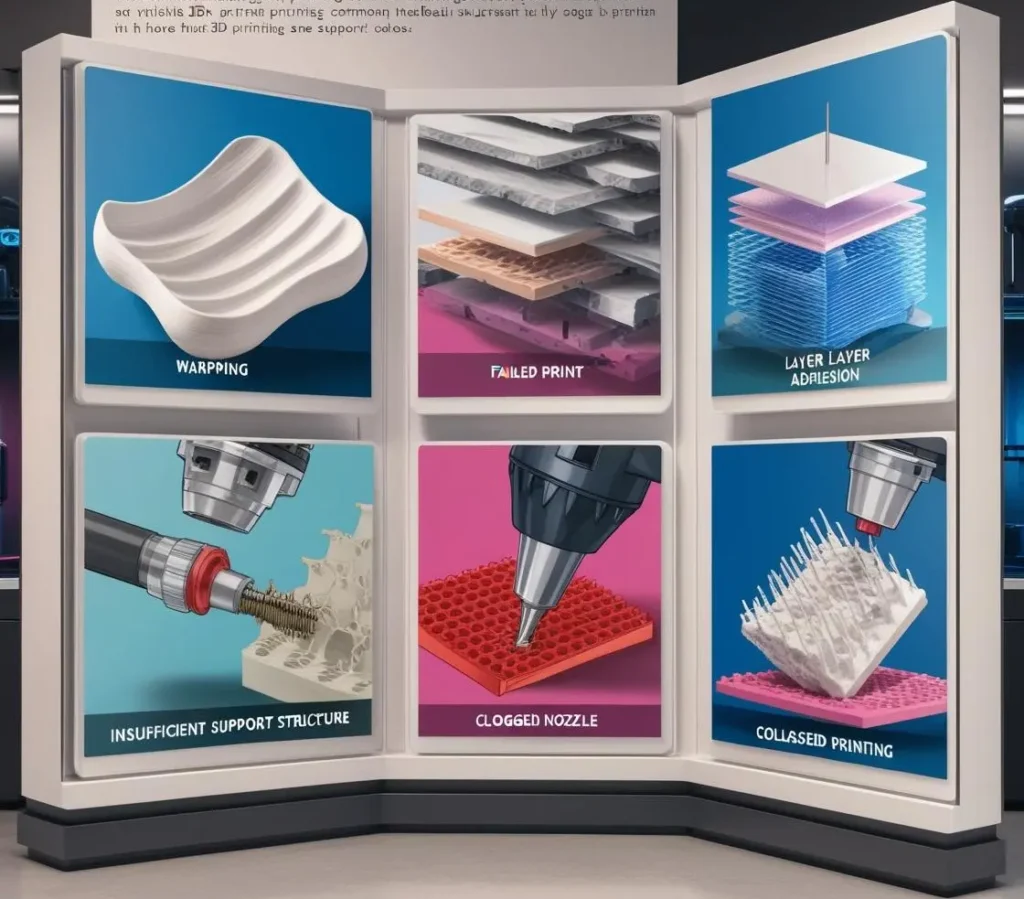

2. Warping and Shrinkage

The Challenge:

Warping occurs when the edges of the print lift during cooling, causing deformation. Shrinkage can lead to size discrepancies in your final print.

Solution:

- Print in a controlled environment to minimize temperature fluctuations.

- Use materials with low shrinkage rates or modify the print’s 3D printer design to include brims or rafts for additional stability.

- Adjust cooling fan settings to control the cooling rate.

3. Overhangs and Unsupported Structures

The Challenge:

Complex designs with overhangs or bridges often result in sagging or failed prints without proper support structures.

Solution:

- Add supports using your slicer software to stabilize the design.

- Use dual-extrusion printers for soluble support materials that can be easily removed.

- Optimize 3D printing and designing by adhering to principles of structural integrity.

4. Stringing and Oozing

The Challenge:

When the printer moves between parts of a design, excess filament can ooze, creating unwanted strings or blobs.

Solution:

- Enable retraction settings in the slicer to pull back filament when the nozzle is moving.

- Adjust nozzle temperature to prevent overheating the filament.

- Clean the nozzle regularly to ensure smooth extrusion.

Advancements in 3D printer technologies now offer more precise filament control, minimizing stringing issues.

5. Material Limitations

The Challenge:

Each material behaves differently during the printing process. For instance, PLA is easy to use but not durable, while ABS requires a heated chamber to prevent warping.

Solution:

- Match the material to the project requirements. For example, use flexible filaments for wearables and strong materials like PETG for mechanical parts.

- Store filaments in a moisture-free environment to prevent degradation.

- Familiarize yourself with emerging materials by staying updated on 3D printer technologies.

6. Inconsistent Print Quality

The Challenge:

Blobs, gaps, and uneven layers are signs of poor print quality, often caused by fluctuating temperatures or improper settings.

Solution:

- Calibrate the printer frequently, ensuring components like belts and rods are tight.

- Adjust slicer settings such as layer height, print speed, and infill percentage.

- Upgrade to high-quality components or 3D printer designs with advanced precision features.

7. Nozzle Clogging

The Challenge:

Clogged nozzles interrupt the printing process and can damage the print head if not addressed promptly.

Solution:

- Use high-quality filaments to avoid debris buildup.

- Regularly clean the nozzle with a cleaning filament or needle.

- Monitor the printing temperature to ensure it matches the filament’s requirements.

Understanding the intricacies of 3D printer technologies can help in diagnosing and fixing nozzle issues.

8. Limited Build Volume

The Challenge:

Desktop 3D printers often have restricted build volumes, making it difficult to print large objects.

Solution:

- Divide larger designs into smaller components and assemble them post-printing.

- Invest in printers with larger build sizes if your projects demand it.

- Adjust your 3D printer design to make efficient use of available space.

9. Post-Processing Needs

The Challenge:

Even with advanced printers, post-processing like sanding, painting, or polishing is often required to achieve a finished look.

Solution:

- Use appropriate tools for smoothing surfaces, such as sandpaper, acetone vapors, or polishing machines.

- Design prints with minimal post-processing needs by leveraging optimized 3D printing and designing techniques.

10. Lack of Knowledge and Training

The Challenge:

Beginners often struggle to navigate the technical aspects of 3D printer technologies, leading to frustration and wasted resources.

Solution:

- Invest in comprehensive training on 3D printing and designing, CAD modeling, and troubleshooting.

- Stay updated on the latest trends and innovations in the field.

- Practice with simple designs before tackling complex projects.

The Importance of Training in 3D Printing

Mastering 3D printing requires more than just technical know-how; it demands a thorough understanding of 3D printer design, material properties, and advanced troubleshooting techniques.

At our institution, we offer some of the best 3D printing courses in India, tailored to equip you with the skills needed to excel in this field. Our programs include:

- 6-Month CAD Modeling and 3D Printing Course: A comprehensive program focusing on 3D printer technologies and hands-on experience.

- 3-Month Short-Term 3D Printing Course: Perfect for professionals looking to enhance their expertise in 3D printer design and applications.

Join us to become proficient in 3D printing and designing and pave the way for a successful career in this revolutionary technology.

3D printing is an exciting and dynamic field, but it comes with challenges that require knowledge, precision, and creativity to overcome. By understanding these common hurdles and implementing the solutions discussed above, you can enhance your printing experience and achieve exceptional results.

Whether you’re a beginner or a professional, mastering 3D printer technologies can help you unlock the full potential of this incredible innovation. And if you’re looking to take your skills to the next level, enroll in our industry-leading 3D printing courses in India today!