3D printing, also known as additive manufacturing, has transformed industries worldwide by enabling the creation of complex objects layer by layer with unparalleled precision. This revolutionary technology has roots dating back several decades, evolving into a powerful tool for innovation. The combination of 3D printing and designing has opened doors to creativity and efficiency in various sectors, from healthcare to aerospace. In this blog, we’ll explore the fascinating journey of 3D printing, from its inception to its modern-day applications.

The Origins of 3D Printing

The concept of 3D printing began in the early 1980s, when the idea of additive manufacturing was first introduced. Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute was one of the pioneers in the field, developing a rapid prototyping system that used a photopolymer resin to create 3D models. However, Kodama’s work remained largely theoretical, as he was unable to secure the necessary patents to bring his vision to life.

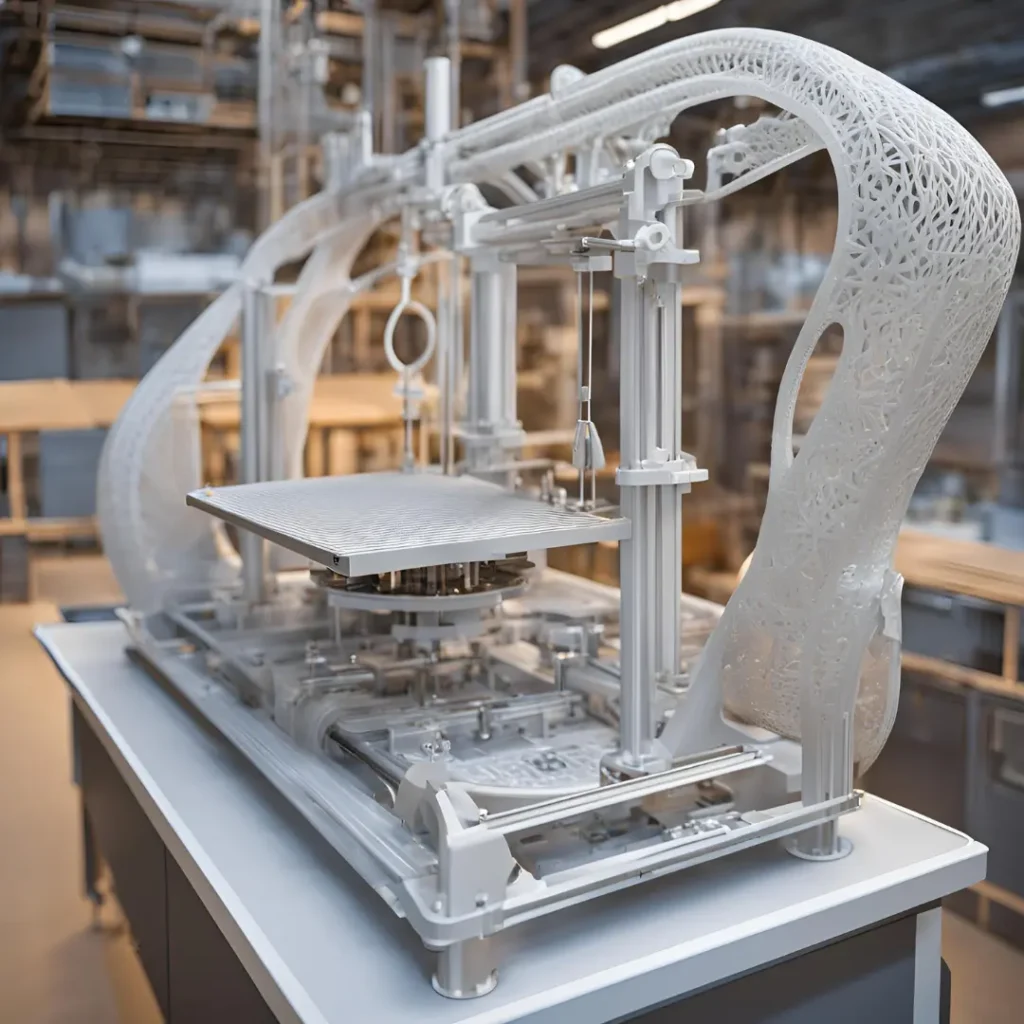

In 1986, Charles Hull, an American engineer, brought 3D printing to the forefront by inventing stereolithography (SLA). Hull’s technique involved curing layers of photopolymer resin with ultraviolet light to create a solid object. This invention laid the foundation for modern 3D printing and designing, and Hull went on to co-found 3D Systems, a company that remains a key player in the industry.

The Growth of 3D Printing in the 1990s

The 1990s witnessed significant advancements in 3D printing technology. Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) emerged during this time, diversifying the methods available for creating 3D objects.

- Selective Laser Sintering (SLS): Invented by Dr. Carl Deckard, this technique involved using lasers to fuse powdered materials like plastics and metals into solid structures.

- Fused Deposition Modeling (FDM): Patented by Scott Crump, this method utilized a heated nozzle to deposit layers of thermoplastic material, forming durable and precise objects.

These technologies expanded the possibilities of 3D printing and designing, allowing for the creation of more intricate and functional prototypes.

3D Printing in the 21st Century: A New Era

The 2000s marked the transition of 3D printing from a niche technology to a mainstream phenomenon. Several factors contributed to this transformation:

- Patent Expirations: Many of the foundational patents for 3D printing expired in the early 2000s, allowing more companies to enter the market and develop affordable 3D printers.

- Open-Source Movement: The RepRap project, launched in 2005, aimed to create self-replicating 3D printers. This initiative encouraged collaboration among developers and enthusiasts, driving innovation in 3D printing and designing.

- Material Advancements: The development of new materials, including biodegradable plastics, metals, and composites, expanded the range of applications for 3D printing.

During this period, industries such as healthcare, automotive, and aerospace began adopting 3D printing for prototyping, custom manufacturing, and even end-use production.

Modern Applications of 3D Printing

Today, 3D printing and designing have become indispensable in various sectors:

- Healthcare: From prosthetics and dental implants to bioprinting tissues and organs, 3D printing is revolutionizing medical treatments.

- Aerospace: Aircraft manufacturers use 3D printing to produce lightweight, durable components that enhance performance and reduce costs.

- Construction: Large-scale 3D printers are being used to construct homes, bridges, and other infrastructure efficiently.

- Consumer Goods: Customizable products like jewelry, footwear, and eyewear are now accessible thanks to advancements in 3D printing technology.

- 3D Printing Food: Edible materials are used as “ink” in 3D food printing to produce elaborate patterns and personalised meals. Layer by layer, ingredients such as dough, chocolate, purees, and even protein pastes are extruded to create delicious works of art.

The Future of 3D Printing Technology

The future of 3D printing is bright, with ongoing research and development aimed at pushing the boundaries of what this technology can achieve. Innovations in materials, speed, and precision promise to make 3D printing and designing even more accessible and impactful. Furthermore, the integration of artificial intelligence and machine learning is expected to enhance design automation, making 3D printing smarter and more efficient.

Why Choose Us for 3D Printing Education?

If you’re fascinated by 3D printing and designing and want to master this transformative technology, our institution is the ideal choice. We are recognized as one of the best institutes providing 3D printing courses in India, offering comprehensive programs tailored to beginners and professionals alike.

- 6-Month CAD Modeling and 3D Printing Course: Dive deep into the fundamentals of design and hands-on 3D printing, gaining expertise in industry-standard tools and techniques.

- 3-Month Short-Term 3D Printing Course: Perfect for those looking to quickly improve or explore the basics of 3D printing technology.

Join us to become part of a community of innovators shaping the future. Enroll today and unlock the endless possibilities of 3D printing and designing!